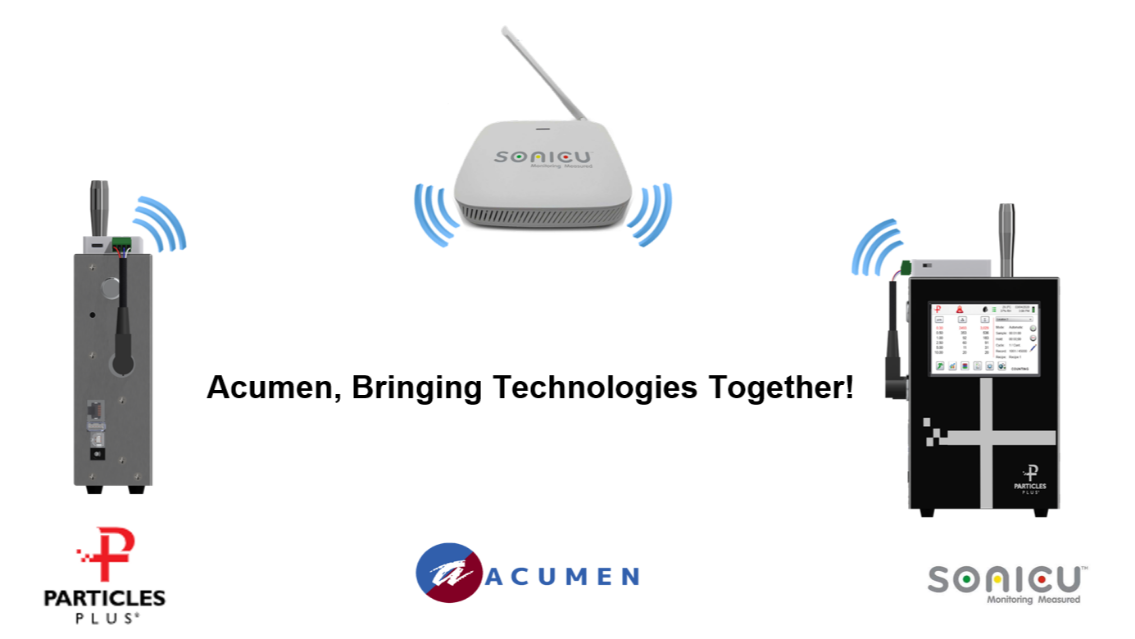

1. Installation of wireless particle counters and cleanroom environmental monitoring systems

Sensors, particle counters

The first step in your real-time cleanroom monitoring solution is the installation of high-precision particle counters and sensors throughout the cleanroom environment. These are strategically placed to measure critical parameters including particle count, air quality, temperature, humidity, differential pressure, and more.

Sonicloud cleanroom monitoring software

These sensors are connected to the Sonicloud platform, a central monitoring system that continuously collects, organizes, and secures data from the sensors in real-time.

2. Data collection and analysis

Continuous data flow Your data is visualized in real-time on dashboards that display current conditions and historical trends.

Data analysis

The system uses advanced algorithms to analyze the data, identifying excursions and automatically alerting operators.

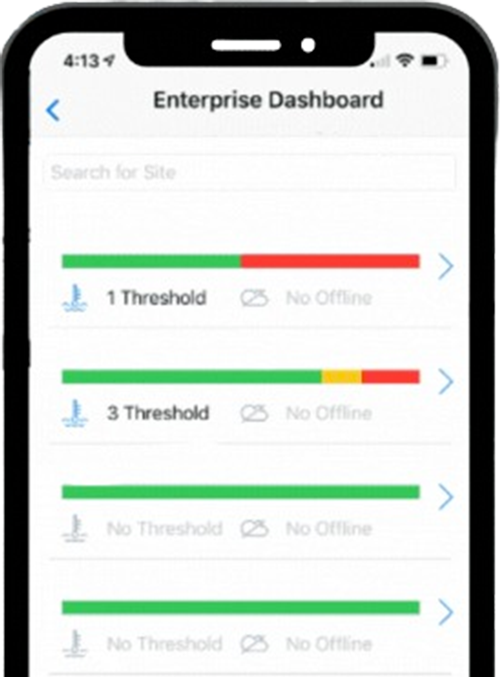

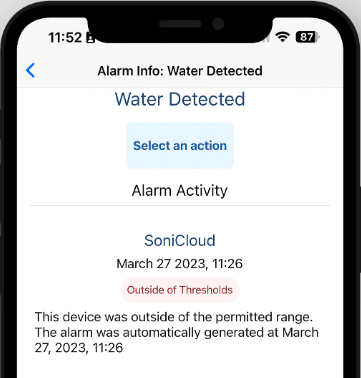

3. Automated alerts and responses

3. Automated alerts and responses

Alert system

When the system detects any parameter is outside the acceptable range, it triggers an automated alert. Alerts can be customized based on your internal role responsibilities, and resolved on computer, tablet, or smartphone.

4. Compliance and documentation

4. Compliance and documentation

Compliance monitoring

Real-time monitoring ensures the cleanroom continuously meets regulatory and industry standards. This is critical for industries like pharmaceuticals, biotechnology, and semiconductor manufacturing, where even minor deviations can cause millions in damages to the business.

Automated documentation

The Sonicu platform also logs all the data and any incidents, creating an audit trail that is essential for regulatory compliance. This documentation can be automatically generated, saving, saving time and reducing the risk of human error.

5. Continuous improvement

Feedback loop

The data collected through real-time monitoring can and should be used to continuously improve the cleanroom's operation. By analyzing trends and identifying areas for improvement, the system can help optimize your cleanroom's performance over time. For example, you might be able to adjust the airflow in your HVAC system and save 15% of the ongoing associated costs.